PRODUCTS

-

Measurement calibration of temperature sensor

-

Measurement calibration of temperature and humidity test equipment

-

Measurement calibration of temperature and humidity indicator (meter)

-

Measurement calibration of surface thermometer

-

Measurement calibration of radiation thermometer

-

Measurement calibration of thermometer

-

Measurement calibration of temperature secondary instrument

-

Pressure measurement calibration

-

Other thermal metering equipment

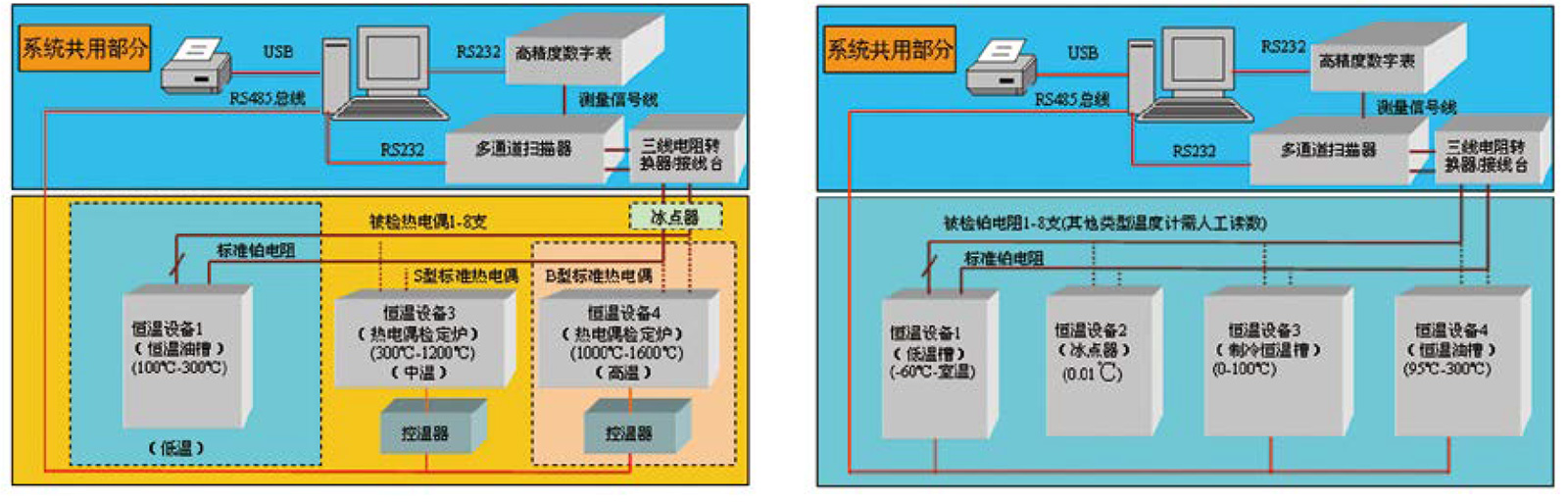

NM-01 Automatic Calibration System of Thermocouples and Resistance Thermometers / Thermocouple and Resistance Thermometer Calibration System

Thermocouple and Resistance Thermometer Calibration System Product Overview:

NM-01 Automatic Calibration System of Thermocouples and Resistance Thermometers is mainly composed of a computer, a multi-channel scanner, a high-precision digital meter, a three-wire resistance converter / junction board, a thermocouple calibration furnace, an intelligent precision temperature control device, a water (oil) bath, a calibrator and a freezing point detector. The system takes computer as the core, controls the multi-channel scanner, the high-precision digital meter and the constant temperature equipment. It automatically completes the calibration work of thermocouple, resistance thermometer and thermometer. The system function and technical index completely meet the requirements of Calibration Specification for Auto-measuring System of Thermocouples and Resistance Thermometers (JJF 1098-2003).

Application of Thermocouple and Resistance Thermometer Calibration System :

The system has been widely used in industries including aviation, aerospace, electric power, petroleum, chemical industry, metallurgy, steel, pharmacy, metrology and military industry, colleges and universities, as well as many scientific research institutions. The system can automatically complete the metrological verification/calibration work of thermocouple (S、R、B、K、N、J、E、T、EA-2equal graduation), resistance thermometer (Pt10、Pt100、Cu50、Cu100、Pt-X、Cu-X), bimetallic thermometer, filled system thermometer, liquid-in-glass thermometer, etc.

Compliance with the following regulations: :

| S/N | Regulation (Standard) Code | Regulation (Standard) Name |

|

1 |

JJG141-2013 |

Verification Regulation of Working Noble Metal Thermocouples |

|

2 |

JJG351-1996 |

Verification Regulation of Base Metal Thermocouples |

|

3 |

JJG668-1997 |

Verification Regulation of Working Platinum-10% Rhodium/Platinum and Platinum-13% Rhodium/Platinum Thermocouple with Short Length |

|

4 |

JJG368-2000 |

Verification Regulation of Working Copper / Copper-Nickel Thermocouple |

|

5 |

JJF1262-2010 |

Calibration Specification for Sheathed Thermocouples |

|

6 |

JJF1183-2007 |

Calibration Specification of the Temperature Transmitter |

|

7 |

JJG229-2010 |

Verification Regulation of Industry Platinum and Copper Resistance Thermometers |

|

8 |

JJF1098-2003 |

Calibration Specification for Auto-measuring System of Thermocouples and Resistance Thermometers |

|

9 |

JJG130-2011 |

Verification Regulation of Liquid-in-Glass Thermometers for Working |

|

10 |

JJG310-2002 |

Verification Regulation of Filled System Thermometers |

|

11 |

JJG226-2001 |

Verification Regulation of Bimetallic Thermometers |

Product Features of Thermocouple and Resistance Thermometer Calibration System: :

★The scanning switch is made of silver-clad material, and the parasitic potential is less than 0.2uV.

★The scanner and three-wire resistance converter / junction board adopt low potential terminals, which reduces the parasitic potential of each link from front-end wiring to data scanning and acquisition.

★The three-wire resistance converter and the junction board are designed in combination, which can be compatible with the wiring of thermocouple, two-wire resistance thermometer, three-wire resistance thermometer and four-wire resistance thermometer. It can automatically complete the switching function of three-wire resistance thermometer during calibration, and eliminate the internal lead resistance of three-wire resistance thermometer.

★Tailor-made special rack for calibration furnace makes it convenient for users to install the furnace and connect wires.

★The reference end compensation of thermocouple during calibration can be freezing point compensation or automatic room temperature compensation.

★An intelligent instrument is adopted for the calibration furnace and thermostatic bath to automatically control the temperature. The thermostatic equipment can quickly reach the set temperature without overshoot. Through computer communication, the automatic switching of temperature points in the calibration process can be realized without manual intervention.

★For temperature control, the photoelectric isolated high-precision solid-state relay triggered by AC zero crossing, which reduces the interference of the temperature control part to the calibration system and the power grid.

★The system software displays the set temperature, actual temperature, temperature alteration ratio, calibration operation time, temperature record curve and other state information in the calibration process in real time.

★The system software has the power down protection function, and supports continuous calibration after the power supply is restored.

★The system automatically generates the calibration data record form, calibration certificate or calibration result notice. The form format can be designed by users according to requirements.

★The data records are stored in the database, which makes it convenient for users to query the data records and output the calibration data. Database management operation functions, such as database backup and database emptying, are available.

★ The system is independently developed, with fully independent intellectual property rights, and software upgrade is guaranteed.

System Composition Block Diagram - Thermocouple Calibration System Composition Block Diagram - Thermocouple Calibration

Technique Parameters::

★Parasitic potential of scanning switch: ≤0.2μV

★Accuracy(Keithley2000):potential measurement error: ≤±(0.005%×Reading+0.0035%×Range)

resistance measurement error: ≤±(0.01%×Reading+0.0035%×Range) (Keithley2010):

Potential measurement error::≤±(0.0037%×Reading+0.0009%×Range)

Resistance measurement error:≤±(0.0052%×Reading+0.0009%×Range)

★Resolution(Keithley2000): potential: 0.1μV resistance: 0.1mΩ(Keithley2010):potential: 0.01μV, resistance: 0.01mΩ

★Temperature control accuracy: the temperature deviation from the calibration point shall not exceed ±5℃ during calibration of the thermocouple, or ±2℃ during calibration of the resistance thermometer.

★Temperature control stability: thermocouple calibration furnace: ≤0.2℃/6min; Thermostatic bath≤0.02℃/10min

★Calibration temperature range: -100℃~1600℃(users can choose thermostatic equipment as needed.)