NM-01 Thermocouple and Thermal Resistance Automatic Calibration System

Key words:

Classification:

Product Description

Product Overview

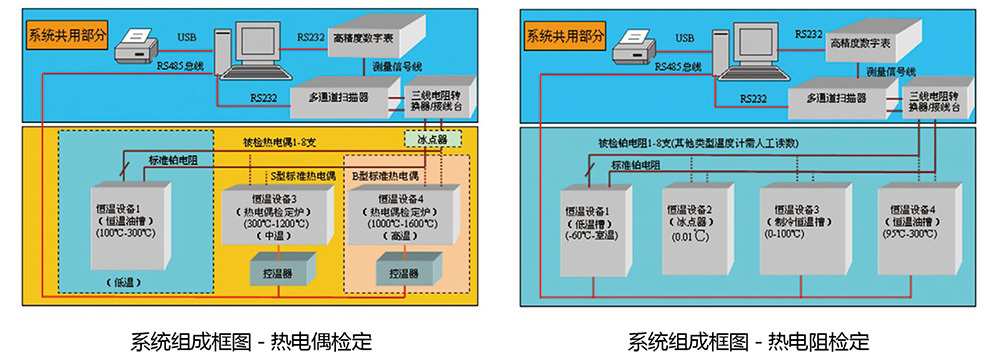

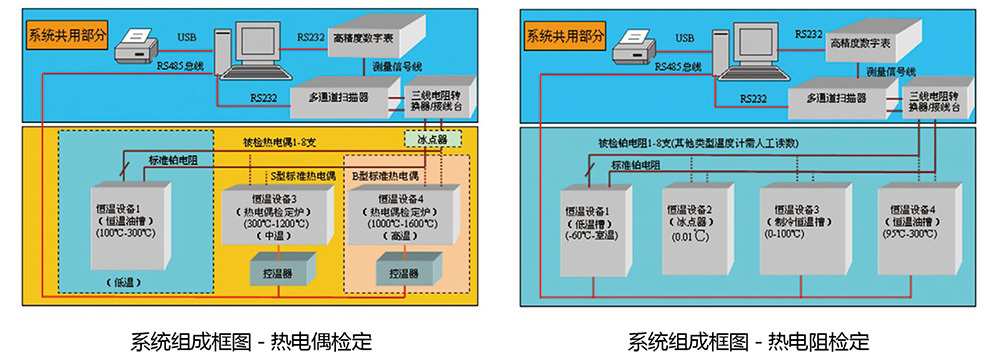

The NM-01 thermocouple and thermal resistance automatic calibration system consists of a computer, multi-channel scanner, high-precision digital meter, three-wire resistance converter/terminal block, thermocouple calibration furnace, intelligent precision temperature control device, water (oil) bath, standard device, ice point device, etc. The system is computer-centered, controlling the multi-channel scanner, high-precision digital meter, and constant temperature equipment, automatically completing the calibration of thermocouples, thermal resistances, and thermometers. The system functions and technical specifications fully comply with JJF1098-2003 "Calibration Specification for Automatic Measurement Systems of Thermocouples and Thermal Resistances" requirements.

Application Scope

The system is widely used in aviation, aerospace, electric power, petroleum, chemical industry, metallurgy, steel, pharmaceuticals, metrology, military industry, universities, and many research institutions. It automatically completes the measurement and calibration of thermocouples (S, R, B, K, N, J, E, T, EA-2, etc.), thermal resistances (Pt10, Pt100, Cu50, Cu100, Pt-X, Cu-X), bimetallic thermometers, pressure thermometers, glass liquid thermometers, etc.

Compliance with Specifications

| Serial Number |

Specification (Range) Code |

Specification (Range) Name |

| 1 |

JJF1637-2017 |

Calibration Specification for Noble Metal Thermocouples |

| 2 |

JJG141-2013 |

Calibration Procedure for Working Noble Metal Thermocouples |

| 3 |

JJF1991-2022 |

Short Type Calibration Specification for Noble Metal Thermocouples |

| 4 |

JJG75-2022 |

Calibration Procedure for Standard Platinum-Rhodium 10-Platinum Thermocouples |

| 5 |

JJG368-2000 |

Calibration Procedure for Working Copper-Copper Nickel Thermocouples |

| 6 |

JJF1262-2010 |

Calibration Specification for Armored Thermocouples |

| 7 |

JJF1183-2007 |

Calibration Specification for Temperature Transmitters |

| 8 |

JJG229-2010 |

Calibration Procedure for Industrial Platinum and Copper Thermal Resistances |

| 9 |

JJF1098-2003 |

Calibration Specification for Automatic Measurement Systems of Thermocouples and Thermal Resistances |

| 10 |

JJG130-2011 |

Calibration Procedure for Working Glass Liquid Thermometers |

| 11 |

JJF1908-2021 |

Calibration Specification for Bimetallic Thermometers |

| 12 |

JJF1909-2021 |

Calibration Specification for Pressure Thermometers |

| 13 |

AMS2750G-2022 |

AEROSPACE MATERIAL SPECIFICATION (R) Pyrometry |

Product Features

★ The scanning switch uses a large area of silver-plated material, with a parasitic potential of less than 0.2uV.

★ The scanner and three-wire resistance converter/terminal block both use specially processed low-potential terminals, reducing parasitic potential from the front-end wiring to data scanning and collection.

★ The combination design of the three-wire resistance converter and terminal block can accommodate connections for thermocouples, two-wire thermal resistances, three-wire thermal resistances, and four-wire thermal resistances, and can automatically complete the lead switching function during the calibration of three-wire thermal resistances, eliminating the internal lead resistance of three-wire thermal resistances.

★ Custom-designed calibration furnace special rack facilitates user operations such as loading the furnace and wiring.

★ Reference end compensation during thermocouple calibration can use ice point compensation or room temperature automatic compensation.

★ The calibration furnace and constant temperature bath use intelligent instruments for automatic temperature control, allowing the constant temperature equipment to quickly reach the set temperature without overshoot. Through computer communication, automatic switching of temperature points during calibration can be achieved without manual intervention.

★ Temperature control uses opto-isolation, high precision, AC zero-crossing triggered solid-state relays, reducing interference from the temperature control part to the calibration system itself and the power grid.

★ The system software displays real-time status information during the calibration process, including set temperature, actual temperature, temperature change rate, calibration working time, and temperature recording curve.

★ The system software has a power failure protection function, allowing calibration to continue after power is restored.

★ Automatically generates calibration data record forms, calibration certificates, or calibration result notifications. Users can design the table format according to their requirements.

★ Data records are stored in a database, allowing for easy data record queries and output of calibration data. It provides database management functions such as database backup and database clearing.

★ The system software includes a self-developed mobile thermal engineering APP, enabling remote operation, data transmission, and real-time monitoring of intelligent devices, as well as functions such as fault reporting, practical tools, and electronic manuals.

★ Independently developed, with complete independent intellectual property rights, software upgrades are guaranteed.

Technical Parameters

★ Scanning switch parasitic potential: ≤ 0.2μV

★ Accuracy (Keithley2010): Potential measurement error: ≤ ±(0.0037%*Reading+0.0009%*Range)

Resistance measurement error: ≤ ±(0.0052%*Reading+0.0009%*Range)

★ Resolution (Keithley2010): Potential: 0.01μV Resistance: 0.01mΩ

★ Temperature control accuracy: During thermocouple calibration, temperature deviation from the calibration point does not exceed ±5℃; during thermal resistance calibration, temperature deviation from the calibration point does not exceed ±2℃.

★ Temperature control stability: Thermocouple calibration furnace ≤ 0.2℃ / 6min; constant temperature bath ≤ 0.02℃ / 10min

★ Calibration temperature range: -100℃ to 1600℃ (users can select constant temperature equipment as needed)

- 产品描述

-

- Commodity name: NM-01 Thermocouple and Thermal Resistance Automatic Calibration System

The NM-01 thermocouple and thermal resistance automatic calibration system consists of a computer, multi-channel scanner, high-precision digital meter, three-wire resistance converter/terminal block, thermocouple calibration furnace, intelligent precision temperature control device, water (oil) bath, standard device, and ice point device.

Product Overview

The NM-01 thermocouple and thermal resistance automatic calibration system consists of a computer, multi-channel scanner, high-precision digital meter, three-wire resistance converter/terminal block, thermocouple calibration furnace, intelligent precision temperature control device, water (oil) bath, standard device, ice point device, etc. The system is computer-centered, controlling the multi-channel scanner, high-precision digital meter, and constant temperature equipment, automatically completing the calibration of thermocouples, thermal resistances, and thermometers. The system functions and technical specifications fully comply with JJF1098-2003 "Calibration Specification for Automatic Measurement Systems of Thermocouples and Thermal Resistances" requirements.

Application Scope

The system is widely used in aviation, aerospace, electric power, petroleum, chemical industry, metallurgy, steel, pharmaceuticals, metrology, military industry, universities, and many research institutions. It automatically completes the measurement and calibration of thermocouples (S, R, B, K, N, J, E, T, EA-2, etc.), thermal resistances (Pt10, Pt100, Cu50, Cu100, Pt-X, Cu-X), bimetallic thermometers, pressure thermometers, glass liquid thermometers, etc.

Compliance with Specifications

Serial Number

Specification (Range) Code

Specification (Range) Name

1

JJF1637-2017

Calibration Specification for Noble Metal Thermocouples

2

JJG141-2013

Calibration Procedure for Working Noble Metal Thermocouples

3

JJF1991-2022

Short Type Calibration Specification for Noble Metal Thermocouples

4

JJG75-2022

Calibration Procedure for Standard Platinum-Rhodium 10-Platinum Thermocouples

5

JJG368-2000

Calibration Procedure for Working Copper-Copper Nickel Thermocouples

6

JJF1262-2010

Calibration Specification for Armored Thermocouples

7

JJF1183-2007

Calibration Specification for Temperature Transmitters

8

JJG229-2010

Calibration Procedure for Industrial Platinum and Copper Thermal Resistances

9

JJF1098-2003

Calibration Specification for Automatic Measurement Systems of Thermocouples and Thermal Resistances

10

JJG130-2011

Calibration Procedure for Working Glass Liquid Thermometers

11

JJF1908-2021

Calibration Specification for Bimetallic Thermometers

12

JJF1909-2021

Calibration Specification for Pressure Thermometers

13

AMS2750G-2022

AEROSPACE MATERIAL SPECIFICATION (R) Pyrometry

Product Features

★ The scanning switch uses a large area of silver-plated material, with a parasitic potential of less than 0.2uV.

★ The scanner and three-wire resistance converter/terminal block both use specially processed low-potential terminals, reducing parasitic potential from the front-end wiring to data scanning and collection.

★ The combination design of the three-wire resistance converter and terminal block can accommodate connections for thermocouples, two-wire thermal resistances, three-wire thermal resistances, and four-wire thermal resistances, and can automatically complete the lead switching function during the calibration of three-wire thermal resistances, eliminating the internal lead resistance of three-wire thermal resistances.

★ Custom-designed calibration furnace special rack facilitates user operations such as loading the furnace and wiring.

★ Reference end compensation during thermocouple calibration can use ice point compensation or room temperature automatic compensation.

★ The calibration furnace and constant temperature bath use intelligent instruments for automatic temperature control, allowing the constant temperature equipment to quickly reach the set temperature without overshoot. Through computer communication, automatic switching of temperature points during calibration can be achieved without manual intervention.

★ Temperature control uses opto-isolation, high precision, AC zero-crossing triggered solid-state relays, reducing interference from the temperature control part to the calibration system itself and the power grid.

★ The system software displays real-time status information during the calibration process, including set temperature, actual temperature, temperature change rate, calibration working time, and temperature recording curve.

★ The system software has a power failure protection function, allowing calibration to continue after power is restored.

★ Automatically generates calibration data record forms, calibration certificates, or calibration result notifications. Users can design the table format according to their requirements.

★ Data records are stored in a database, allowing for easy data record queries and output of calibration data. It provides database management functions such as database backup and database clearing.

★ The system software includes a self-developed mobile thermal engineering APP, enabling remote operation, data transmission, and real-time monitoring of intelligent devices, as well as functions such as fault reporting, practical tools, and electronic manuals.

★ Independently developed, with complete independent intellectual property rights, software upgrades are guaranteed.

Technical Parameters

★ Scanning switch parasitic potential: ≤ 0.2μV

★ Accuracy (Keithley2010): Potential measurement error: ≤ ±(0.0037%*Reading+0.0009%*Range)

Resistance measurement error: ≤ ±(0.0052%*Reading+0.0009%*Range)

★ Resolution (Keithley2010): Potential: 0.01μV Resistance: 0.01mΩ

★ Temperature control accuracy: During thermocouple calibration, temperature deviation from the calibration point does not exceed ±5℃; during thermal resistance calibration, temperature deviation from the calibration point does not exceed ±2℃.

★ Temperature control stability: Thermocouple calibration furnace ≤ 0.2℃ / 6min; constant temperature bath ≤ 0.02℃ / 10min

★ Calibration temperature range: -100℃ to 1600℃ (users can select constant temperature equipment as needed)

Production Equipment

If you are interested in this product, please fill in the following information and submit it to us, we will arrange professionals to contact us as soon as possible!

Related Products

Related Products