NM-HTS series precision constant temperature bath

Key words:

Classification:

Product Description

Product Overview

This series of constant temperature baths is mainly used for the verification and calibration of thermistors, low-temperature thermocouples, glass liquid thermometers, bimetallic thermometers, pressure thermometers, etc. It adopts a dual-tank stirring working method, separating the verification working area from the heating and cooling mixing area of the constant temperature bath, reducing operational noise, improving the technical performance of the machine, and expanding the effective working area. It uses a Pt100 platinum resistance temperature sensor and an intelligent PID controller for automatic temperature control, featuring short transition time, long stability time, and high reliability.

Product Features

★ Adopts a dual-tank stirring working method, ensuring good temperature uniformity.

★ Uses digital PID automatic temperature control technology, providing good temperature stability.

★ Optional RS232/RS485 communication interface for convenient computer control.

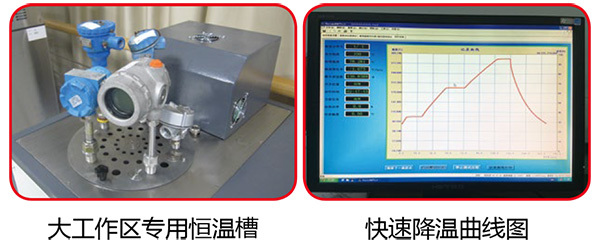

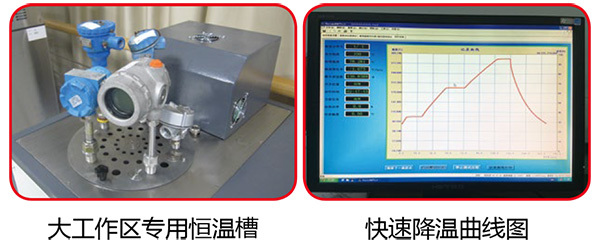

★ Optional liquid level protection, built-in smoke exhaust, and rapid cooling functions.

★ The optional liquid level protection function can prevent heating when the liquid level in the constant temperature bath is insufficient, avoiding safety accidents.

★ The optional built-in smoke exhaust function collects and discharges high-temperature oil smoke, which is beneficial for maintaining a clean working environment and protecting the health of workers, while also facilitating oil smoke purification and protecting the natural environment.

★ The optional rapid cooling function allows for multiple cycles of high and low temperature points in one day, improving work efficiency. It also reduces the working time of the working medium at high temperatures, extending the service life of the working medium.

Technical Parameters

| Product Model |

NM-HTS95 |

NM-HTS300 |

NM-HTS300L Special for Transmitter Calibration |

| Temperature Range |

Room Temperature +10℃~ 95℃ |

95℃~ 300℃ |

95℃~ 300℃ |

| Operation Mode |

Normal / Human-Machine Interface |

||

| Optional Functions |

Liquid Level Protection / Built-in Smoke Exhaust / Rapid Cooling / Oil Smoke Purification |

||

| Temperature Fluctuation |

≤ ±0.01℃ / 30 minutes |

≤ ±0.015℃ / 30 minutes |

|

| Temperature Uniformity |

≤ 0.01℃ |

≤ 0.01℃ |

≤ 0.02℃ |

| Working Area Dimensions |

Φ130×450(mm) |

Φ300×400(mm) |

|

| External Dimensions |

700×600×1280(mm) |

950×750×1250(mm) |

|

| Working Medium |

Soft Water |

Methyl Silicone Oil (201 ~ 50 Type) |

Methyl Silicone Oil (201 ~ 50 Type) |

| Weight |

100kg |

120kg |

150kg |

| Total Power |

1.5 ~ 2.8kW |

4kW |

|

| Power Supply |

220VAC, 50Hz |

||

- 产品描述

-

- Commodity name: NM-HTS series precision constant temperature bath

This series of constant temperature baths is mainly used for the verification and calibration of thermistors, low-temperature thermocouples, glass liquid thermometers, bimetallic thermometers, pressure thermometers, etc. It adopts a dual-tank stirring working method, separating the verification working area from the heating and cooling mixing area of the constant temperature bath, which reduces operational noise, improves the technical performance of the device, and expands the effective working area. It uses a Pt100 platinum resistance temperature sensor and an intelligent PID controller to achieve automatic temperature control, featuring short transition time, long stability time, and high reliability.

Product Overview

This series of constant temperature baths is mainly used for the verification and calibration of thermistors, low-temperature thermocouples, glass liquid thermometers, bimetallic thermometers, pressure thermometers, etc. It adopts a dual-tank stirring working method, separating the verification working area from the heating and cooling mixing area of the constant temperature bath, reducing operational noise, improving the technical performance of the machine, and expanding the effective working area. It uses a Pt100 platinum resistance temperature sensor and an intelligent PID controller for automatic temperature control, featuring short transition time, long stability time, and high reliability.Product Features

★ Adopts a dual-tank stirring working method, ensuring good temperature uniformity.

★ Uses digital PID automatic temperature control technology, providing good temperature stability.

★ Optional RS232/RS485 communication interface for convenient computer control.

★ Optional liquid level protection, built-in smoke exhaust, and rapid cooling functions.

★ The optional liquid level protection function can prevent heating when the liquid level in the constant temperature bath is insufficient, avoiding safety accidents.

★ The optional built-in smoke exhaust function collects and discharges high-temperature oil smoke, which is beneficial for maintaining a clean working environment and protecting the health of workers, while also facilitating oil smoke purification and protecting the natural environment.

★ The optional rapid cooling function allows for multiple cycles of high and low temperature points in one day, improving work efficiency. It also reduces the working time of the working medium at high temperatures, extending the service life of the working medium.

Technical Parameters

Product Model

NM-HTS95

NM-HTS300

NM-HTS300L Special for Transmitter Calibration

Temperature Range

Room Temperature +10℃~ 95℃

95℃~ 300℃

95℃~ 300℃

Operation Mode

Normal / Human-Machine Interface

Optional Functions

Liquid Level Protection / Built-in Smoke Exhaust / Rapid Cooling / Oil Smoke Purification

Temperature Fluctuation

≤ ±0.01℃ / 30 minutes

≤ ±0.015℃ / 30 minutes

Temperature Uniformity

≤ 0.01℃

≤ 0.01℃

≤ 0.02℃

Working Area Dimensions

Φ130×450(mm)

Φ300×400(mm)

External Dimensions

700×600×1280(mm)

950×750×1250(mm)

Working Medium

Soft Water

Methyl Silicone Oil (201 ~ 50 Type)

Methyl Silicone Oil (201 ~ 50 Type)

Weight

100kg

120kg

150kg

Total Power

1.5 ~ 2.8kW

4kW

Power Supply

220VAC, 50Hz

Production Equipment

If you are interested in this product, please fill in the following information and submit it to us, we will arrange professionals to contact us as soon as possible!

Related Products

Related Products